描述

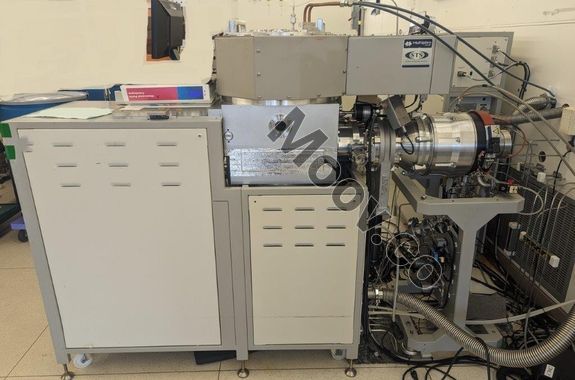

The system uses SF6, C4F8, O2 and N2 as the primary gases, and the owner believes it also has an input for Argon, though it wasn’t used. The main coil power supply is a 1000W RF generator (ENI ACG-10B) and they think the platen has a 300W power supply (ENI ACG-3) . It has helium backside cooling and a heat exchanger for process temperature control but it’s standard temperature range (they think 45C). This system has the turbo pump and controller, but does not have the process backing pumps (chamber and loadlock pumps).There is a gas box, the two wall-mounted control cabinets, and a small rack that holds the turbo controller and RF power supplies. This system has a mechanical clamp to hold the wafer and is configured for 150mm substrates. STS Multiplex ICP Etcher , Metal Cluster STS Dielectric PECVD ,- 50 Hz, – 400 Volts , 2001 Vintage STS AOE Dielectric ICP Etcher, – 400 V, – 50 Hz STS Advanced Silicon DRIE Etch,2002 Vintage STS M/PLEX Multiplex ICP Etcher SPTS / STS Versalis fxP Etcher – It is configured for autoloading 200mm wafers – It has two process chambers: – CVE – XeF2 etch chamber (isotropic etching of Si) – CVD – oxide, nitride, and silicon – It does not have the Rapier chamber to run the DRIE Bosch process. 2018 Vintage STS Multiplex HRM ICP – Platen size: 4 in – Electrostatic Chuck – Gases: SF6: 450.00 sccm Eetch Cycle C4F8: 200.00 sccm Passivation Cycle O2: 450.00 sccm Eetch Cycle SPTS / STS Sigma fxP PVD,2023 Vintage STS Multiplex ICP Etcher – 400V – 50Hz – 3 Phase With: – MAG 900 CT turbopump – Power distribution & control rack cabinet with power distribution – Electrogrip electrostatic driver – vAT PM-7 adaptive pressure controller – Leybold Mag Drive 1000 pump controller – ENI ACG-10B RF generator – ENI ACG-3B-06 RF generator – ENI VL-400 phase shift controller – PowerBright VC-2000 step-up/down transformer – BOC Edwards iQDP-80 roughing pump – Neslab RTE-211 recirculating chiller – Gas cabinet – LEP300 control server – Configured for 3in substrates 2001 Vintage Plasmatherm / STS Vision 320 Mark II RIE Etcher STS MULTIPLEX systems, including a cluster metal ICP, dielectric PECVD, DRIE etch, and ICP etch. STS MULTIPLEX Dielectric PECVD STS MULTIPLEX ASE Silicon DRIE Etch STS MULTIPLEX AOE Dielectric ICP Etch STS Multiplex ICP system Used STS MULTIPLEX ICP STS MULTIPLEX STS multiplex dual chamber only DRIE equipment STS ASE ICP DRIE It was purchased new . This tool was used for low volume a few hours per week, over the time it was installed. It was maintained under a service contract during operation, and was deinstalled in working condition. Designed for silicon etching with gases plumbed for SF6, C4F8, N2, O2, and Ar Includes an add-on module for XeF2 isotropic silicon etching Tooling compatible with both 100 mm and 150 mm wafers Unique cyclical etching capability: alternating phases of etch and passivation enable deep, highly anisotropic etching results Capable of etching depths exceeding 500 microns and aspect ratios up to 20:1 with exceptional precision This STS ASE system remains a top choice for deep reactive-ion etching applications requiring fine control and high aspect ratio trenches, widely used in MEMS and microfabrication research.配置

無配置OEM 代工型號說明

Etchers & Ashers文檔

無文檔

類別

Dry / Plasma Etch

上次驗證: 超過30天前

關鍵商品詳情

條件:

Refurbished

作業狀態:

未知

產品編號:

138671

晶圓尺寸:

6"/150mm

年份:

2001

Logistics Support

Available

Transaction Insured by Moov

Available

Refurbishment Services

Available

STS

MULTIPLEX DRIE

類別

Dry / Plasma Etch

上次驗證: 超過30天前

關鍵商品詳情

條件:

Refurbished

作業狀態:

未知

產品編號:

138671

晶圓尺寸:

6"/150mm

年份:

2001

Logistics Support

Available

Transaction Insured by Moov

Available

Refurbishment Services

Available

描述

The system uses SF6, C4F8, O2 and N2 as the primary gases, and the owner believes it also has an input for Argon, though it wasn’t used. The main coil power supply is a 1000W RF generator (ENI ACG-10B) and they think the platen has a 300W power supply (ENI ACG-3) . It has helium backside cooling and a heat exchanger for process temperature control but it’s standard temperature range (they think 45C). This system has the turbo pump and controller, but does not have the process backing pumps (chamber and loadlock pumps).There is a gas box, the two wall-mounted control cabinets, and a small rack that holds the turbo controller and RF power supplies. This system has a mechanical clamp to hold the wafer and is configured for 150mm substrates. STS Multiplex ICP Etcher , Metal Cluster STS Dielectric PECVD ,- 50 Hz, – 400 Volts , 2001 Vintage STS AOE Dielectric ICP Etcher, – 400 V, – 50 Hz STS Advanced Silicon DRIE Etch,2002 Vintage STS M/PLEX Multiplex ICP Etcher SPTS / STS Versalis fxP Etcher – It is configured for autoloading 200mm wafers – It has two process chambers: – CVE – XeF2 etch chamber (isotropic etching of Si) – CVD – oxide, nitride, and silicon – It does not have the Rapier chamber to run the DRIE Bosch process. 2018 Vintage STS Multiplex HRM ICP – Platen size: 4 in – Electrostatic Chuck – Gases: SF6: 450.00 sccm Eetch Cycle C4F8: 200.00 sccm Passivation Cycle O2: 450.00 sccm Eetch Cycle SPTS / STS Sigma fxP PVD,2023 Vintage STS Multiplex ICP Etcher – 400V – 50Hz – 3 Phase With: – MAG 900 CT turbopump – Power distribution & control rack cabinet with power distribution – Electrogrip electrostatic driver – vAT PM-7 adaptive pressure controller – Leybold Mag Drive 1000 pump controller – ENI ACG-10B RF generator – ENI ACG-3B-06 RF generator – ENI VL-400 phase shift controller – PowerBright VC-2000 step-up/down transformer – BOC Edwards iQDP-80 roughing pump – Neslab RTE-211 recirculating chiller – Gas cabinet – LEP300 control server – Configured for 3in substrates 2001 Vintage Plasmatherm / STS Vision 320 Mark II RIE Etcher STS MULTIPLEX systems, including a cluster metal ICP, dielectric PECVD, DRIE etch, and ICP etch. STS MULTIPLEX Dielectric PECVD STS MULTIPLEX ASE Silicon DRIE Etch STS MULTIPLEX AOE Dielectric ICP Etch STS Multiplex ICP system Used STS MULTIPLEX ICP STS MULTIPLEX STS multiplex dual chamber only DRIE equipment STS ASE ICP DRIE It was purchased new . This tool was used for low volume a few hours per week, over the time it was installed. It was maintained under a service contract during operation, and was deinstalled in working condition. Designed for silicon etching with gases plumbed for SF6, C4F8, N2, O2, and Ar Includes an add-on module for XeF2 isotropic silicon etching Tooling compatible with both 100 mm and 150 mm wafers Unique cyclical etching capability: alternating phases of etch and passivation enable deep, highly anisotropic etching results Capable of etching depths exceeding 500 microns and aspect ratios up to 20:1 with exceptional precision This STS ASE system remains a top choice for deep reactive-ion etching applications requiring fine control and high aspect ratio trenches, widely used in MEMS and microfabrication research.配置

無配置OEM 代工型號說明

Etchers & Ashers文檔

無文檔