描述

-ALD cluster tool for GaN gate dielectric deposition -ALD DEPOSITION N3TB -spec MF-00038796配置

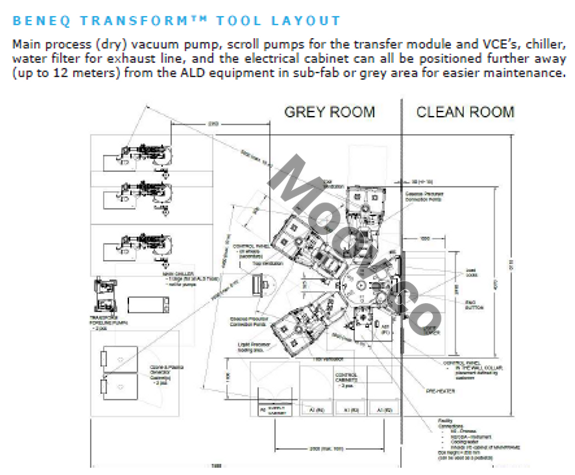

BENEQ Transform ALD Cluster ToolSubstrate type - 8" (200 mm) GaN-on-Silicon Lot Size - 25 Wafers ALD process batch size - 1 pcs for PEALD 25 pcs for batch ALD MainframeMx600SS - Brooks with Tool Commander and Fab LinkMx600SS (Super-Six) vacuum transfer system for up to 4 PM's -MagnaTran7 vacuum transfer robot-Two vacuum cassette elevators (VCE)-Optical aligner for wafer/notch alignment-Requires two rough pumps (for TM and VCE's), provided by the customer - Maximum four process modules (e.g. pre-clean, pre-heat, ALD) -Internal 4 wafer buffer for dummy wafer management or wafer cooling -Integrated TopCooler wafer cooling module-Compatible with ultra-clean environmentsScheduler and Human Machine Interface (HMI)-HMI (E95) for tool operationSECS/GEM communication interface-SECS-II messaging (E5), GEM (E30) with HSMS protocol (E37)-Through-the-wall assembly-Auto-door option for VCE's-Facility water used for process module cooling Process module PM1Pre-heatingInfrared Pre-heat module-For rapid, in-vacuum infrared heating of wafers prior to ALD process- Thermocouple-based temperature measurement Process module PM2Beneq C2 Batch ALDBeneq C2 process module for 25 wafer ALD deposition-SEMI S2 and S8 compatible- Fully automated wafer indexing inside the reactor-Four independent heated liquid source cabinets with precursor canister (max. fill 3 liter) -Option for two cross-flow gas lines (Os and NHS)- Includes foreline particle trap to protect vacuum pump-Process kit including three sets of wetted parts (reactor, cassette, gas distribution unit)Ozone sourceOzone cross-flow gas- Including O, generator and gas sensor Process module PM3Beneq C2 SW-PE ALDBeneq C2 process module for single wafer plasma ALD deposition-SEMI S2 and S8 compatible-Plasma (remote or direct modes)-Carrier gas line (N2/Ar)- NH3 plasma gas line-Option for second plasma gas line (O2)-Four independent heated liquid source cabinets with precursor canister (max. fill 3 liter)-Option for two cross-flow gas lines (03 and NH3)- Includes foreline particle trap to protect vacuum pump-Process kit including three sets of wetted parts (reactor, cassette, gas distribution unit) Ozone sourceOzone cross-flow gas- Including Os generator and gas sensor-Source is shared between the PEALD process modules Process module PM4Beneq C2 SW-PE ALDBeneq C2 process module for single wafer plasma ALD deposition-SEMI $2 and $8 compatible-Plasma (remote or direct modes)-Carrier gas line (N/Ar)-O; plasma gas line-Option for second plasma gas line (NH3)-Four independent heated liquid source cabinets with precursor canister (max. fill 3 liter) -Option for two cross-flow gas lines (Os and NH3)- Includes foreline particle trap to protect vacuum pump-Process kit including three sets of wetted parts (reactor, cassette, gas distribution unit) Shared ozone source Additional Options:Cassette bar code readerOCR wafer readerAdditional SECS/GEM featuresCustomer preferred pumping kit integration (BOC Edwards ixh1210 HT for process, ix1120N for TM and VCE)Option/readiness for thermal process module swap with PEALD module (see description below)OEM 代工型號說明

未提供文檔

無文檔

BENEQ

Transform

類別

ALD

上次驗證: 超過60天前

關鍵商品詳情

條件:

Used

作業狀態:

未知

產品編號:

133797

晶圓尺寸:

8"/200mm

年份:

2021

Logistics Support

Available

Transaction Insured by Moov

Available

Refurbishment Services

Available

描述

-ALD cluster tool for GaN gate dielectric deposition -ALD DEPOSITION N3TB -spec MF-00038796配置

BENEQ Transform ALD Cluster ToolSubstrate type - 8" (200 mm) GaN-on-Silicon Lot Size - 25 Wafers ALD process batch size - 1 pcs for PEALD 25 pcs for batch ALD MainframeMx600SS - Brooks with Tool Commander and Fab LinkMx600SS (Super-Six) vacuum transfer system for up to 4 PM's -MagnaTran7 vacuum transfer robot-Two vacuum cassette elevators (VCE)-Optical aligner for wafer/notch alignment-Requires two rough pumps (for TM and VCE's), provided by the customer - Maximum four process modules (e.g. pre-clean, pre-heat, ALD) -Internal 4 wafer buffer for dummy wafer management or wafer cooling -Integrated TopCooler wafer cooling module-Compatible with ultra-clean environmentsScheduler and Human Machine Interface (HMI)-HMI (E95) for tool operationSECS/GEM communication interface-SECS-II messaging (E5), GEM (E30) with HSMS protocol (E37)-Through-the-wall assembly-Auto-door option for VCE's-Facility water used for process module cooling Process module PM1Pre-heatingInfrared Pre-heat module-For rapid, in-vacuum infrared heating of wafers prior to ALD process- Thermocouple-based temperature measurement Process module PM2Beneq C2 Batch ALDBeneq C2 process module for 25 wafer ALD deposition-SEMI S2 and S8 compatible- Fully automated wafer indexing inside the reactor-Four independent heated liquid source cabinets with precursor canister (max. fill 3 liter) -Option for two cross-flow gas lines (Os and NHS)- Includes foreline particle trap to protect vacuum pump-Process kit including three sets of wetted parts (reactor, cassette, gas distribution unit)Ozone sourceOzone cross-flow gas- Including O, generator and gas sensor Process module PM3Beneq C2 SW-PE ALDBeneq C2 process module for single wafer plasma ALD deposition-SEMI S2 and S8 compatible-Plasma (remote or direct modes)-Carrier gas line (N2/Ar)- NH3 plasma gas line-Option for second plasma gas line (O2)-Four independent heated liquid source cabinets with precursor canister (max. fill 3 liter)-Option for two cross-flow gas lines (03 and NH3)- Includes foreline particle trap to protect vacuum pump-Process kit including three sets of wetted parts (reactor, cassette, gas distribution unit) Ozone sourceOzone cross-flow gas- Including Os generator and gas sensor-Source is shared between the PEALD process modules Process module PM4Beneq C2 SW-PE ALDBeneq C2 process module for single wafer plasma ALD deposition-SEMI $2 and $8 compatible-Plasma (remote or direct modes)-Carrier gas line (N/Ar)-O; plasma gas line-Option for second plasma gas line (NH3)-Four independent heated liquid source cabinets with precursor canister (max. fill 3 liter) -Option for two cross-flow gas lines (Os and NH3)- Includes foreline particle trap to protect vacuum pump-Process kit including three sets of wetted parts (reactor, cassette, gas distribution unit) Shared ozone source Additional Options:Cassette bar code readerOCR wafer readerAdditional SECS/GEM featuresCustomer preferred pumping kit integration (BOC Edwards ixh1210 HT for process, ix1120N for TM and VCE)Option/readiness for thermal process module swap with PEALD module (see description below)OEM 代工型號說明

未提供文檔

無文檔